This invention relates to a GaAs mosfet and to a method of making a GaAs mosfet and to a mosfet when made by the method. A mosfet is a metal-oxide semiconductor field-effect transistor.

The invention accordingly provides a GaAs mosfet comprising a p-type gallium arsenide single crystal having two grooves formed therein, each groove containing a layer of indium, a layer of dopant overlying the indium and a layer of Al2 O3 overlying the dopant, each groove overlying respective n+ region of the gallium arsenide, the surface of the gallium arsenide single crystal on each side of each groove comprising native oxide to a depth contiguous to the n+ regions, the layers of dopant being in contact with the junctions between the n30 regions and the native oxides, there being provided a flat contact pad covering substantially all the native oxide between the grooves and in contact with the Al2 O3 of both grooves, a second contact pad covering the native oxide on the remaining side of one groove and in contact with the dopant via an electrically ruptured part of the Al2 O3 of that one groove, and a third contact pad covering the native oxide on the remaining side of the other groove and in contact with the dopant via an electrically ruptured part of the Al2 O3 of that other groove.

- Here, GaAs FET was operated as a MOSFET, and it shows high drain current performance when operated in the enhancement mode due to high channel conductivity of GaAs which gives good performance as.

- HEMT and GaAs FET Chips for Lightwave Applications. Fields marked with. are required. Project Information. Contact Information Submit. Submit Quote Request: Buy lblMinQty.

The three contact pads are preferably each of silver. The gallium arsenide single crystal may bear, on a face remote from the grooves, successive layers one of indium and one or more of metals forming ohmic contacts with the p-type gallium arsenide for example one layer of zinc and one layer of silver. The silver overlying the zinc may be connected to a contact wire and to heat sink. Usually, the native oxide under the first contact pad extends continuously from one groove to the other. The invention further provides a method of making a GaAs mosfet, the method comprising:

FORMING TWO GROOVES IN A SURFACE OF A P-TYPE GALLIUM ARSENIDE SINGLE CRYSTAL, DEPOSITING IN EACH GROOVE A LAYER OF INDIUM,

DEPOSITING OVER THE INDIUM IN EACH GROOVE A LAYER OF A DOPANT,

T pain ft chris brown best love song mp3 download. DEPOSITING OVER THE DOPANT A LAYER OF ALUMINIUM, ANODICALLY OXIDISING THE SURFACE OF THE WORK UNTIL ALL THE ALUMINIUM IS OXIDISED TO Al2 O3 and the gallium arsenide is oxidised to a depth contiguous to the dopant,

annealing the work to form an n+ layer in the gallium arsenide under the grooves and contiguous with the anodically oxidised gallium arsenide,

depositing contact metal simultaneously or in any order (i) covering substantially all the anodically oxidised gallium arsenide between the grooves and in contact with both of the layers of Al2 O3, (ii) covering the anodically oxidised gallium arsenide on the remaining side of one groove and in contact with the Al2 O3 of that one groove, and (iii) covering the anodically oxidised gallium arsenide on the remaining side of the other groove and in contact with the Al2 O3 of that other groove,

and rendering electrically conductive Al2 O3 between the dopant and the contact metal (ii) and (iii). The method may further comprise, before or after the annealing, depositing, on a face of the gallium arsenide single crystal remote from the grooves, a layer of indium and layer(s) of metal(s) forming ohmic contacts with the p-type gallium arsenide, for example a layer of zinc adjacent the indium and a layer of silver overlying the zinc.

The dopant may be for example germanium and is conveniently tin.

The contact metal is preferably silver. The annealing preferably lasts from 1 to 10 minutes at a temperature preferably of 300° to 650° C., preferably over 500° C., e.g. 600° C., and is performed in an atmosphere most preferably of nitrogen. Conveniently, the Al2 O3 between the dopant and the contact metal (ii) and (iii) is rendered conductive by applying thereto a voltage sufficient to break down the Al2 O3 but insufficient to break down the anodically oxidised gallium arsenide.

The indium may be deposited by evaporation, e.g. by using a photoresist float-off method. The invention also extends to a GaAs mosfet when made by the method set forth above.

A method according to the invention will now be described by way of example (whereby a mosfet according to the invention will also be described) with reference to the accompanying drawing which shows a cross-section of a mosfet according to the invention.

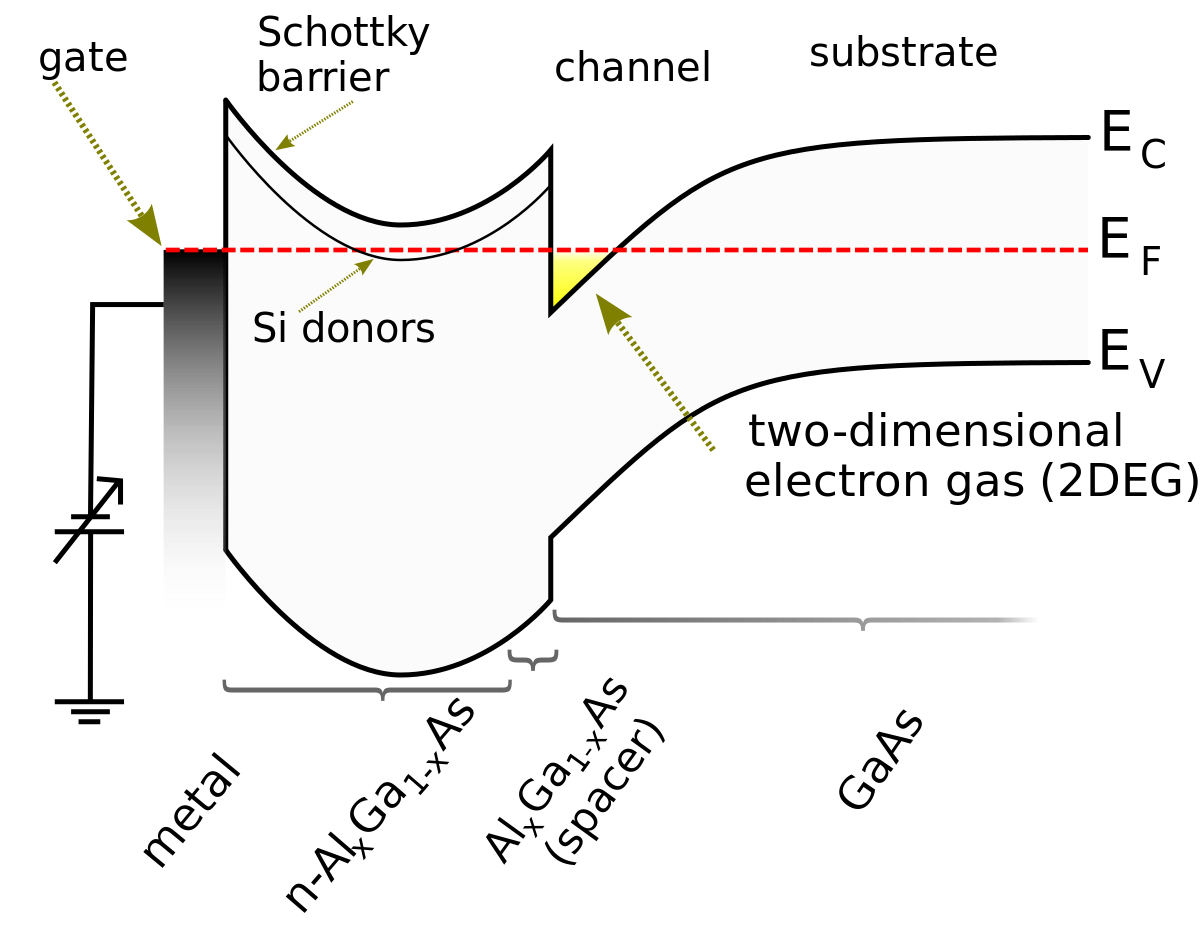

GaAs (Gallium Arsenide) high frequency devices which are the most suitable compound semiconductors for satellite broadcasting receivers, communication receiving devices and satellite communication receivers. In equipment for receiving radio waves from satellites, HEMT devices are used to amplify weak signals without generating noise.

Into a single-crystal block 1 of GaAs (gallium arsenide) of p-type having a hole density of p = 5×1016 cm-3 are etched two parallel channels 2, 3 both 2000A deep, by conventional photolithography and applying an etch solution comprising (by volume) 20 parts H2 O, 4 parts H2 O2 and 1 part of '0.88' NH4 OH, for 15 seconds.

Without removing the photoresist which protected all except the channel areas of the block 1, indium is evaporated on to the block and is accordingly deposited only in the channels 2 and 3, where it forms a layer 5 200A thick. Thereafter a layer 6, 1000A thick, of tin is deposited, followed by a layer 7 of aluminium 500A thick. The layer 5 acts as a wetting or fluxing agent to assist good adhesion of the subsequent layers.

The face of the block 1 including the channels 2, 3 is now subjected to anodic oxidation as described in UK patent application No. 52160/74, that is, in an electrolyte containing for example a mixture of ethylene glycol and 1 part of a 3% by weight aqueous solution of tartaric acid (which aqueous solution was first adjusted using ammonia to a pH of, say, 6), for about 40 or 50 minutes at an initial current density not exceeding 1mA/cm2, e.g. around 0.5mA/cm2. The initial current density must be as low as possible in order that the subsequent annealing (to be described) should give the best results. The anodic oxidation creates simultaneous growth of native GaAs oxide from the block 1 and of Al2 O3 from the layer 7 of aluminium. The anodic oxidation is continued until all of the layer 7 is converted into Al2 O3, at which instant a detectable change in anodisation current does, conveniently, occur. From the known relative oxidation rates of Al and GaAs, the thickness of the native GaAs oxide is deduced to be about 1000A at this instant, the GaAs oxide being shown as dotted region 1a in the drawing. This anodic oxidation method yields a native GaAs oxide stable enough to withstand the next steps.

On the face of the block 1 opposite the channels 2, 3 are evaporated, in order, a layer 10 of indium 200A thick, a layer 11 of zinc 1000A and a layer 12 of silver 2000A thick.

As the next step, the block 1 is annealed for 5 minutes at 600° C. in nitrogen, which is preferable to such atmospheres as hydrogen, oxygen, or argon. This annealing has three purposes: (i) to produce n+ layers (shown as a shaded region 1b in the drawing) by thin phase epitaxy, wherein no arseniferous overpressure is required, thanks to the Al2 O3 layer 7; (ii) to create good electrical interface conditions between the GaAs and the native GaAs oxide; and (iii) to render the back contact (the layers 10, 11 and 12) ohmic. A MOS (metal-oxide semiconductor) sandwich is thus formed.

A second selective evaporation is now performed, whereby silver is deposited at discrete regions 20, 21 and 22, where 20 covers the region between the channels 2 and 3 and partly encroaches on both, and 21 and 22 contact separate parts of the channels 2 and 3 respectively together with the remainder of that face of the block 1. These regions are used as contact pads for receiving e.g. wires, 20 being known as the gate, 21 as the source and 22 as the drain.

To form good contacts between the source 21 and the respective n+ layer 1b and between the drain 22 and the respective n+ layer 1b, a breakdown voltge of 50V is applied to the source 21 and then to the drain 22, thus creating a field of 107 V/cm across the Al2 O3 layer 7, which breaks down at those parts thereof shown cross-hatched. Experiments show that the GaAs native oxide layer 1a does not break until 80V are applied (a field of 8×106 V/cm).

Either before or after this Al2 O3 breakdown step, wires are bonded to the three silver contact pads 20, 21 and 22 and a contact and a heat-sink are applied to the layer 12.

The top surface (as drawn) of the block 1 thus consists only of silver and Al2 O3, which are both relatively inert, mechanically strong and non-volatile, thus protecting the underlying layer structure from volatilisation, chemical break-down of the GaAs oxide and mechanical abrasion. The Al2 O3 layers in addition provide the gate 20 with an overlap, as required, over the n+ Papas freezeriaclout games. layers 1B.

- 144 MHz preamplifier with BF981

Design of a preamplifier for 144 MHz with 1 dB NF and 23 dB gain using BF981. This amplifier is using a low cost silicon MOSFET (BF981 from Philips) to give more than 20 dB gain with around 1 dB noise figure on 2 meter. - VHF UHF preamp

ON6MU project for a vhf uhf preamplifier - U301 FET preamplifier

This FET preamplifier has been around for almost 25 years. It is extremely reliable and can handle several watts directly into either the input or the output without failure. - 2 Meter GaAs FET Preamp

KD9JQ 2 meter GaAsFET preamplifier by KD9JQ - 6m Preamp

A dead easy 50 mhz preamp by VK3CJS - 23 cm GaAs FET preamplifier

On 23cm the best way to obtain a good RX-sensitivity is to use a GaAs-FET in the front-end, since these devices show very low noise figures. - Audio Preamp

Easy circuit that provide good gain to weak audio signals - 144Mhz preamplifier

A preamplifier project based on Rainer DJ9BV project, in french

- 137 kHz antenna preamplifier- A simple 137 kHz antenna preamplifier to make your FT-817 (and others) useable on 2200m band.

- 144 MHz Antenna Pre-Ampilfier- Electronic circuit and components layout fot this VHF Preamp[ Hits: 3176 | Votes: 5 | Rating: 6.4 ]

- 144 MHz preamplifier with BF981- Design of a preamplifier for 144 MHz with 1 dB NF and 23 dB gain using BF981. This amplifier is using a low cost silicon MOSFET (BF981 from Philips) to give more than 20 dB gain with around 1 dB noise figure on 2 meter.

- 144 MHz Very Low Noise Preamplifier - An home made low noise preamplifier project for 144 MHz, with detailed circuit diagram. The VLNA-144 preamplifier has been Published on DUBUS 4 2019[ Hits: 222 | Votes: 2 | Rating: 10 ]

- 144Mhz preamplifier- A preamplifier project based on Rainer DJ9BV project, in french

- 2 Meter GaAs FET Preamp- KD9JQ 2 meter GaAsFET preamplifier by KD9JQ[ Hits: 5606 | Votes: 4 | Rating: 5.75 ]

- 23 cm GaAs FET preamplifier- On 23cm the best way to obtain a good RX-sensitivity is to use a GaAs-FET in the front-end, since these devices show very low noise figures.

- 432MHz Low Noise Preamp- An easy to build with a cheap HEMT FET Transistor Low noise preamplifier with FHX35LG based on JH0WJF design[ Hits: 647 | Votes: 1 | Rating: 10 ]

- 435 plus 1296MHz ATF54143 Pre-amplifier- The prototype for this amplifier was originally designed for 70cm and was used on the 2004 3B9C Dx-pedition to Rodriguez Island for satellite and EME. It had a noise figure of 0.49dB with an associated gain of 20dB.

- 50-70 MHz preamplifier- A ham radio home made preamplifier for 50 MHz and 70 MHz bands[ Hits: 82 | Votes: 1 | Rating: 1 ]

- 6m Preamp- A dead easy 50 mhz preamp by VK3CJS

- Amateur Radio - Microphone Preamp- Low signal, noise-high AC gain preamplifier[ Hits: 955 | Votes: 0 | Rating: 0 ]

- Amplifiers and Vacuum Tubes Tuning Loading and Arcing- Page on amplification topics. From vacuum tubes to various components, discussion on stability and arcin causes.

- Antenna pre-amplifier for 10 m- A simple & effective antenna pre-amp for 10m. Band (28-29.7 MHz)[ Hits: 1692 | Votes: 1 | Rating: 9 ]

- Attenuators and Preamps- How to get the most from attenuators and preamps

- Audio Preamp- Easy circuit that provide good gain to weak audio signals[ Hits: 3716 | Votes: 2 | Rating: 3.5 ]

- Designing Op Amp Audio PreAmplifiers- Design guidelines for Op Amp audio preamplifier circuits by Mike Martell N1HFX

- DL5DBM`s 2 meter Antenna preamp- Homebrew with CF300 DGMF with about .24 dBD gain[ Hits: 3144 | Votes: 5 | Rating: 7.6 ]

- GaAs FER Pre Amp Cookbook- There are many designs for building preamps each with their own advantages and disvantages. In this PDF Article author reviews several different types.

- General purpose RF Wideband PreAmp- General purpose RF Wideband PreAmp based on BSX-20 transistor with a frequency range 14-550 MHz[ Hits: 2346 | Votes: 2 | Rating: 5.5 ]

- Improving Receiver Noise on 50 MHz- Tests on a preamplifier for 50 MHz installed right at the feedpoint of the antenna.

- LF/MF Preamplifier- A universal LF/MF preamplifier by Lyle Koehler, K0LR[ Hits: 2043 | Votes: 2 | Rating: 4.5 ]

- Low Power LF Amplifier- ON6MU Low Power amplifier

- Mic Pre Ampllifier- A microphone preamplifier schematic for hand-helds by ON6MU[ Hits: 1613 | Votes: 2 | Rating: 4 ]

- Mic Preamplifier- Mic Preamp, schematic by Anthony Gargasz, KB8WOW

- Mizuho products- Mizuho Tsushin Co. was a small Japanese manufacturer of QRP radios and kits, shortwave receiver accessories, and AM broadcast band receiver kits and antennas[ Hits: 3169 | Votes: 1 | Rating: 10 ]

- PHEMT (GaAs FET) Preamplifiers- Angle Linear has been producing GaAs FET preamplifiers since 1980

- Radio Preamplifier for 2 mtr reciever- 20db gain 144 Mhz preamplifier by Harry Popov LZ1BB[ Hits: 1931 | Votes: 0 | Rating: 0 ]

- Simple Cheap MMIC Preamps- Who needs a GaAsFET? Tuning, constructions and Packaging by Paul Wade

- The 50MHz Assistant- Preamp & Power Amp By Alkberto, I0XGR[ Hits: 2477 | Votes: 1 | Rating: 10 ]

- Transistor Audio Preamplifier Circuits- Design Guidelines for Bipolar Transistor Audio Preamplifier Circuits By Mike Martell N1HFX

- Tri-Mode Buffer Amplifier Box- The TMB-1 is an RF amplifier unit / receiving accessory that can be used with a low-impedance broadband loop, a high-impedance terminated loop (such as a Pennant, Flag, or Kaz Delta), and whip (telescoping rod) antennas.[ Hits: 911 | Votes: 1 | Rating: 1 ]

- U301 FET preamplifier- This FET preamplifier has been around for almost 25 years. It is extremely reliable and can handle several watts directly into either the input or the output without failure.

- U310 FET preamplifier- Extremely reliable FET preamplifier can handle several watts directly into either the input or the output without failure[ Hits: 984 | Votes: 2 | Rating: 9 ]

- UHF Low Noise Antenna pre-amp- Low Noise Antenna pre-amp for SAT, EME & DX-ing

- VHF UHF preamp- ON6MU project for a vhf uhf preamplifier[ Hits: 13863 | Votes: 21 | Rating: 3.95 ]

- W7IUV HF Preamplifier- Schematic and pictures of a W7IUV preamplifier

- W7IUV Low Band Preamp- Pre amplifier using a 2N5109 for the 160 meters band[ Hits: 2282 | Votes: 6 | Rating: 6.17 ]

- Wideband PreAmp's for HF/VHF/UHF- Wideband VHF/UHF/SHF monolithic PreAmp based on MARx-series by ON6MU

Technical Reference

Search The DXZone.com

Technical Reference : Preamp

About The DXZone.com

Gaafet Technology

Sign up for daily Newsletter

Gaafet Vs Finfet

Free for your Site